Technical Background:

In order to meet various sales requirements and publicity effects, existing cosmetic bottles and caps are printed with ink on the bottle body, causing pollution during the production process and recycling.

Secondly, most bottles are made of PET or glass, while lids are mostly made of PP, PE, ABS, etc. During the recycling process, manual classification is required, which is time-consuming and labor-intensive, and the recycling cost is high.

Two-color injection molding caps and bottles produced by dark pattern molds can solve this problem very well

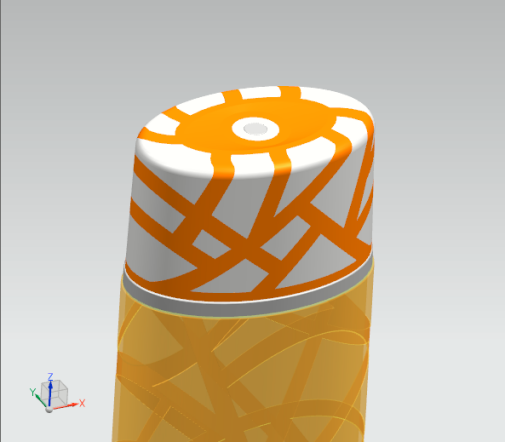

The lid is made of PP raw material and TPE/TPR elastic plastic, and is injection molded in two steps. By optimizing the product design, the lid has 2-3 color combinations, and the unique shape, pattern, logo and other design elements are color-matched, eliminating the need for 2 Material loss caused by secondary processing, while avoiding chemical raw materials produced by electroplating, and ink used in silk screen printing to pollute the environment.

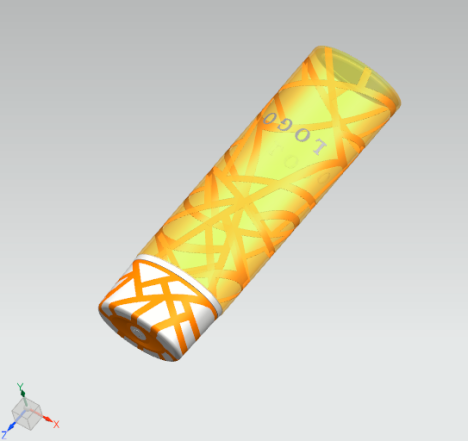

The bottle adopts the dark pattern design of the mold. On the surface of the mold, the lines, patterns, LOGO and other elements that the customer wants are electro-etched out.

When the bottle is blow-molded, it is integrally formed, and subsequent printing is not required, which saves costs and has a remarkable effect in terms of environmental protection.

From the perspective of material recycling, PP, PE or blow molding grade TPE are used, which are all environmentally friendly and recyclable materials. After the customer has used the packaging material, the entire bottle and lid can be mixed, broken, and recycled. There is no need to take out the lid and recycle it. It becomes easy to operate and saves time and labor costs.

Judging from the texture of the bottle, the use of TPE elastic plastic can not only increase the dark texture effect, but also increase the touch feel and achieve a silky feeling similar to skin. When customers use the bottle, they will have a good touch feeling. This is PET The effect cannot be achieved by the material.

Zhenggao has been committed to two-color injection molding of cosmetic lids for many years, and has independently developed a variety of two-color lids. At the same time, it provides customers with technical support services for two-color lids and innovative bottle types.

Foshan Zhenggao Packaging Technology Co., Ltd.

2022-07-15