The following is an optimized design case of the D35-24 tooth hole cover:

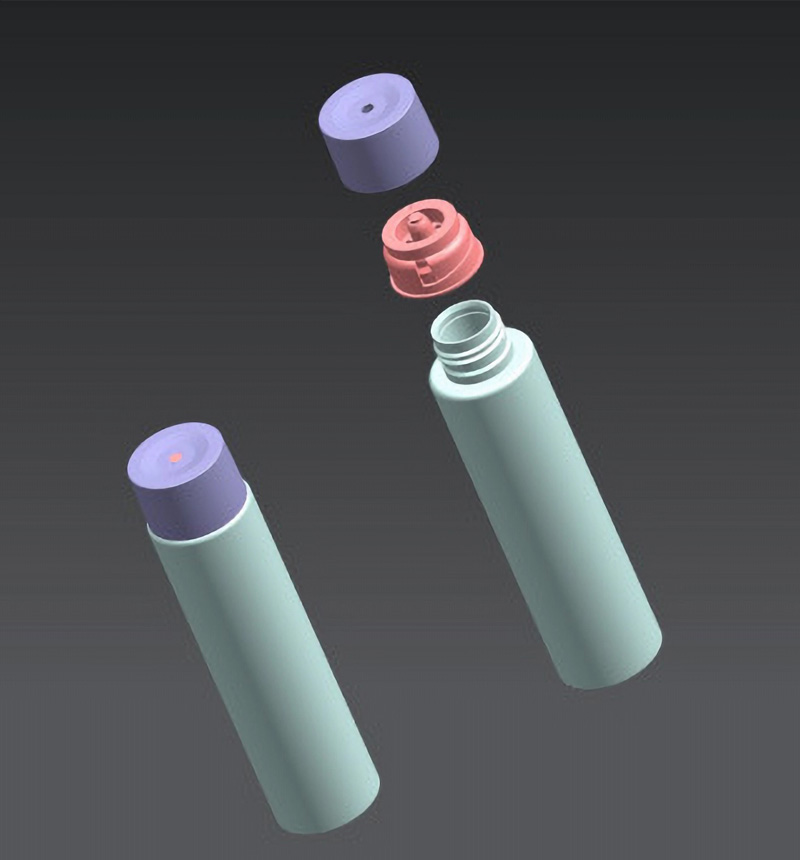

Design plan as shown above:

Inner cover made of: transparent PP material

Outer cover made of: translucent PP material

In order to improve the texture of the surface, the cover adopts the electroplating process of the outer cover;

This increases the cost for processing and pollutes production and recycling.

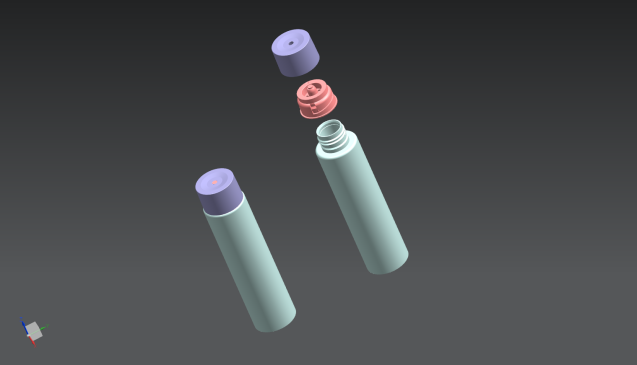

As shown above, the optimized design:

Inner cover: still made of transparent PP material

Outer cover (two-color cover): The inner layer of the cover is made of PP material, and the outer layer is TPE/TPR elastic plastic with PP as the base material;

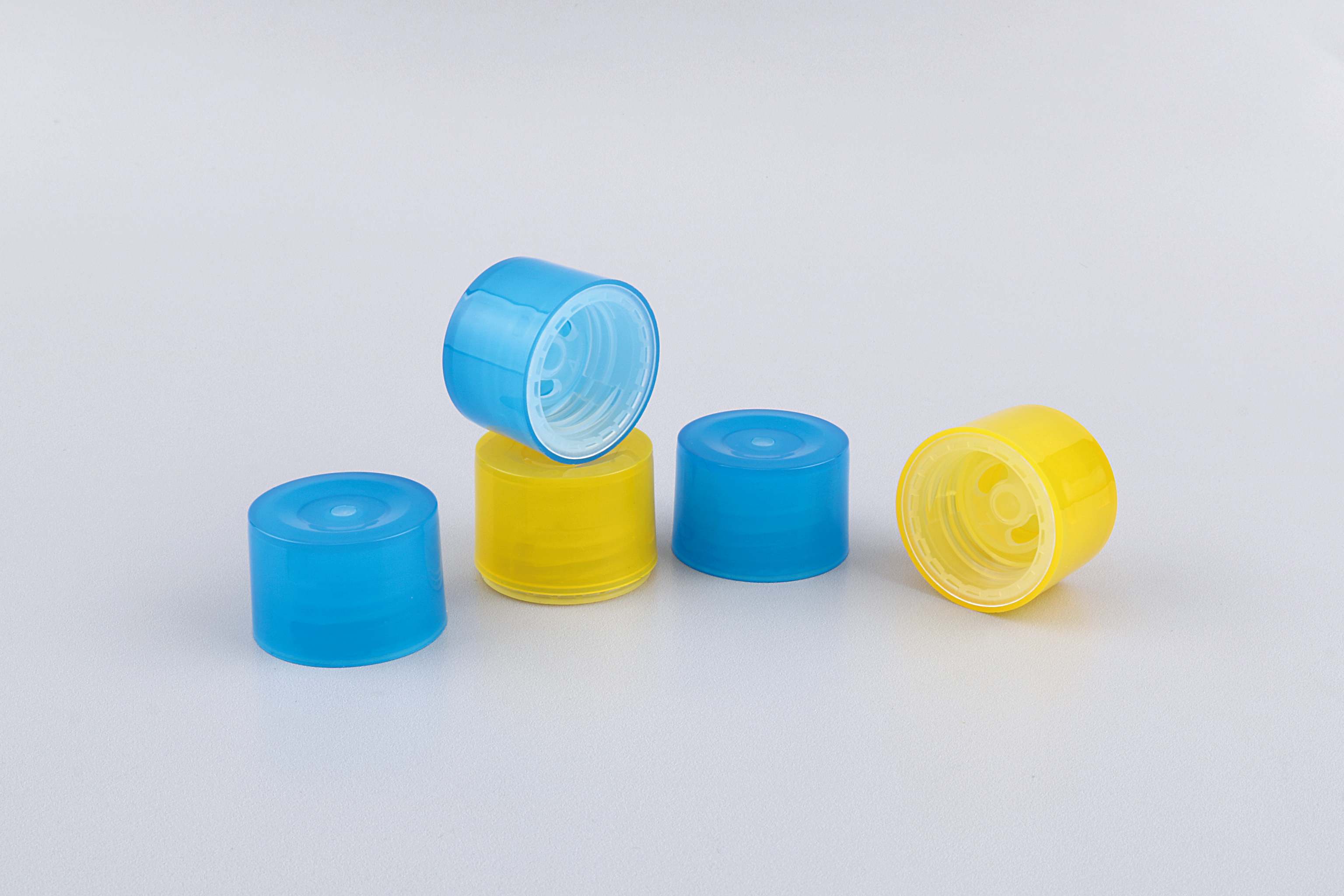

The outer cover is molded in two steps using a two-color injection mold, so that the cover has two colors to match, with unique shapes, patterns, logos and other design elements, eliminating the material loss caused by two processes. The surface adopts a fine frosted effect. , to achieve the effect of improving the surface texture, while avoiding the pollution of the environment caused by electroplating.

Because the outer layer is made of TPE elastic plastic, it can increase the touch feel and achieve a silky feeling similar to skin. When customers use the cover, they will have a good touch feeling.

Through design improvements, the entire set of lids can be broken and recycled. Since the entire set of lids is made of PP base material, after recycling, it can be used for PP products. The surface of the lid will have a good surface effect while achieving the purpose of environmental protection.

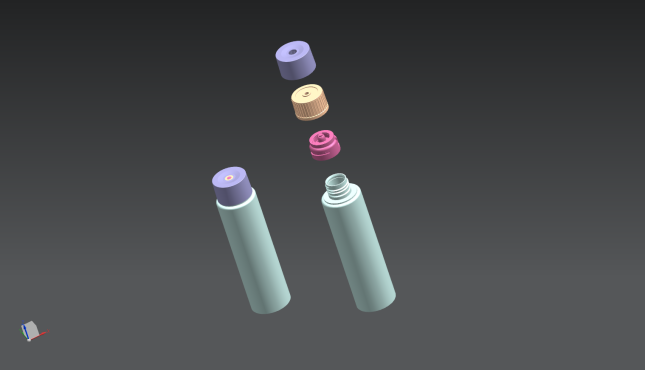

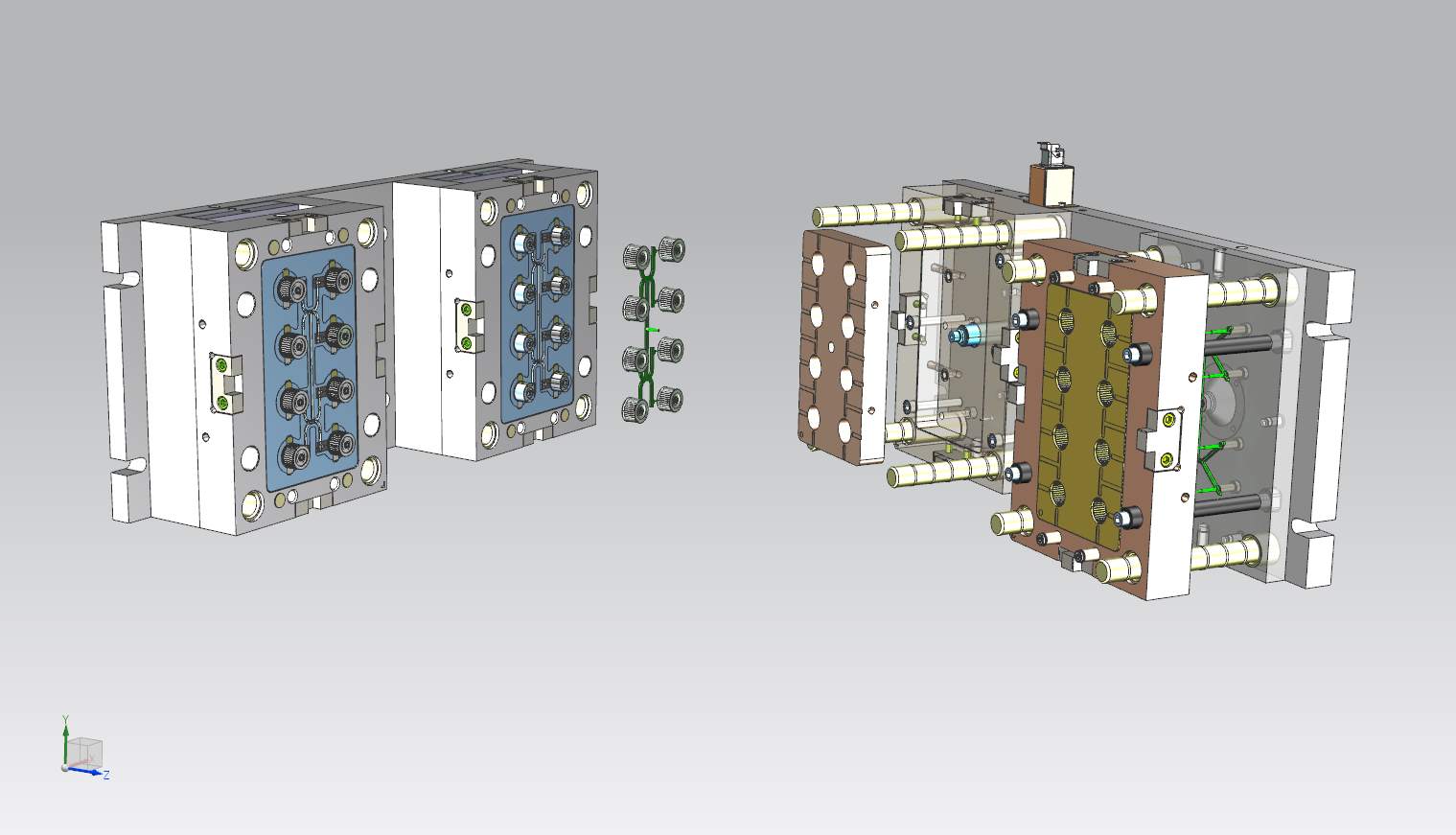

Mold demonstration diagram:

Zhenggao has been committed to two-color injection molding of cosmetic lids for many years, and has independently developed a variety of two-color lids. At the same time, it provides customers with technical support services for two-color lids and innovative bottle types.

Foshan Zhenggao Packaging Technology Co., Ltd.

2022-07-15